Our Testing Capabilities

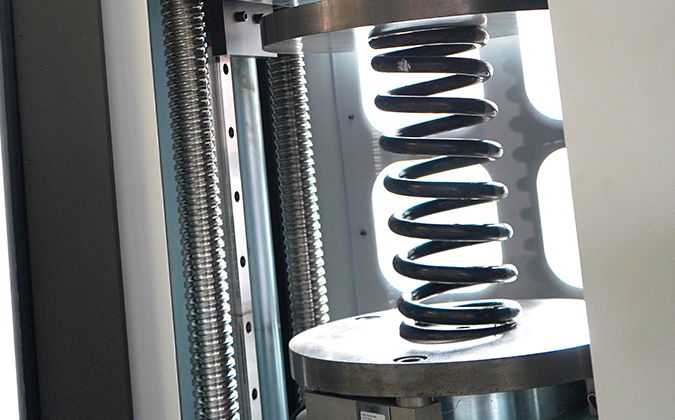

Our specialist spring testing machinery, is capable of load (extension and compression) and torque testing, ranging from 0.4 to 100,000 N of load and 0.005 to 100 Nm of torque.

We have the capacity not only to measure the load or torque at a set deflection, but we can also continuously test the load/torque over a range of defections to confirm the rate is as expected.

Testing is set up to specifications outlined in national, international or internal company standards, and all results are supplied in a simple to analyse test certificate.

Who Uses Us and Why?

We work across the spring supply chain from designers to end-users. Industries include medical, aerospace, automotive, rail, and oil and gas. Typically, load or torque and dimensional tests are performed to:

- Independently confirm the spring is within tolerances specified by the customer, or;

- If there is a discrepancy between what the customer sees and what the manufacture is stating

End-users will find the latter extremely useful as we can identify legitimate reasons for discrepancies between manufacturer and user.

Why Choose Our Testing Facilities

Our static test lab is exclusively tailored for testing springs, and our highly qualified team work with springs day in day out. Meaning our spring knowledge is second to none giving us the edge over other test labs.

If you want to get expert advice about your springs, we are the people to talk to. We can even take on customised test work to suit your precise requirements.

What Else We Can Do

We can measure the dimensions of a spring, including (but not limited to): wire diameter, coil diameter, free length, total coils, end grinding circumference, tip thickness, squareness, parallelism and bow.

Apart from static testing we can also help you with fatigue testing and materials testing.