The Benefits of Shot Peening

Improves the lifespan of a component

Reduces the risk of surface cracks

Helps prevent failures, improves performance

Improves compressive stresses

Removal of burrs, metal flashing and scale

Good to Know

- Typical turnaround times are five days. Please contact us if you need this quicker

- We can shot peen spring wire/section sizes from 0.3mm (0.012″)

- Steel and glass media are available

- Almen strip testing to verify arc height

- We can shot peen anything up to 200mm in length

- Duplex peening and strain peening available.

- We can test peen before an entire batch to ensure you are getting the desired result

- Rigorous quality control to ISO 9001

- Backed by over 40 years of technical know-how. Fully supported service

- If your client requires independent shot peening services, we can assit you

Post Peening Services

We have a range of post-peening services that can enhance a components life further. These include:

- Low-temperature heat treatment

- Oiling

- Degreasing

- Pre-stressing to stabilise dimensions

- Fatigue testing to validate the shot peening process

Get a quote for shot peening

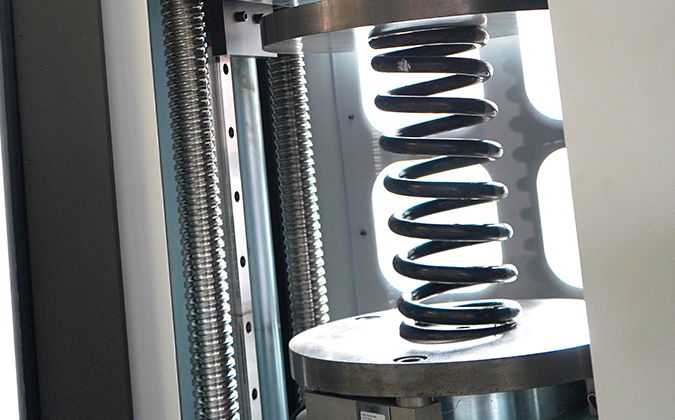

What is Shot Peening?

Shot peening is the process of accelerating small, rounded particles (shot) at the surface of a component. The shot is propelled using air or discharged by centrifugal force from an impeller wheel.

When the shot particles strike a component’s surface, they cause the surface to deform plastically, with hammerhead like impressions into the surface. As a result, it increases the fatigue life of springs and other components.

One of the reasons for this increased life is due to compressive residual stresses imparted on the surface of the component, where the operational stresses are at a maximum.

Read our technical article about shot peening…

April 29, 2020

Residual Stresses Due to Shot Peening in Springs

What is Typically Shot Peened?

While our service focuses on springs, we do shot peen many other components. Typical components include:

- Aerospace components

- Automotive components

- Components for the oil and gas industry

- Medical implants

- Seal rings

- Springs

We have to ability to shot peen anything up to 200mm in length. Then, depending on the size of the target component (and the residual stresses required), we can shot peen using different media types, including glass and steel.