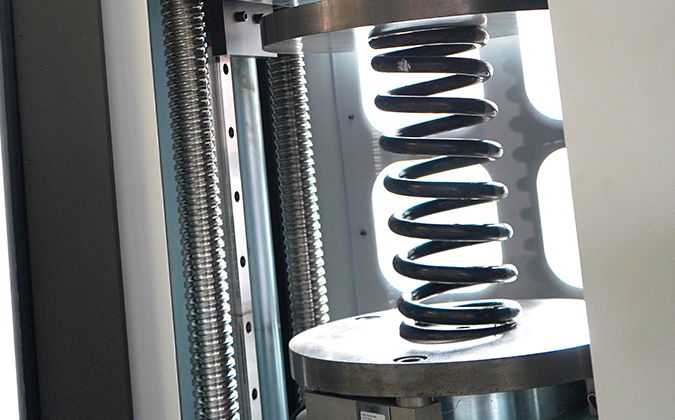

Springs are highly stressed critical components that must undertake millions of cycles during their life.

Customers demand longevity and high performance from a product, because of this it’s important to understand how your spring will behave. Fatigue testing is a method of working a spring until it breaks. This gives you an accurate determination of how long that spring will last in service. As an impartial association our testing facilities can independently verify your springs, giving confidence that they are fit for purpose and will achieve that given life.

The Institute of Spring technology has been conducting fatigue tests on springs for over 50 years. This gives us the edge when it comes to problem solving spring failures as there’s not a lot we haven’t seen before. Fatigue testing can be undertaken at any stage of the springs journey, whether the spring is a new or existing design, being subjected to a more demanding application, validating a new or existing supplier or even a change in the material. We’ve seen many types of springs come through our test labs from the underwire used in bras and swimwear, to the spring used in the mechanism of the Under Control football training aid, and, torsion springs used on a trucks anti-spillage system.

Testing can be both interesting and challenging, but we work closely with our customers to fully understand what their requirements are. When we receive a spring for fatigue verification, we conduct a brief spring design assessment to check the test parameters / requirements to establish the most appropriate fatigue test machine. The spring design details (i.e. material type, wire size, outside diameter, number of coils, free length and test lengths) are input into our Spring Calculator Professional software from which the most appropriate test speed is established. This is either 1/13th of the springs natural frequency or the maximum speed of the test machine, whichever is lowest.

The medical sector is one such sector where spring performance is vital. The implications of a spring failing prematurely can have serious consequences, impacting on the supply of equipment, service interruptions and at worse treatment delay. We regularly support the medical sector as their demand for excellence is high. Recently an end user was experiencing failures in a compression spring much earlier than expected. They did not know why this failure was occurring so approached us to investigate. After several batches of the spring was commissioned from different manufacturers and after running our fatigue tests, we were able to replicate the problem. With careful review of the fatigue data it was decided a re-design of the spring was necessary, we also recommended that the spring should under-go shot peening. Once the proposed changes were implemented the springs life increased to an acceptable level and the customer was given the confidence that the spring was achieving the desired repeatable product life.

The experience and knowledge we have means we can diagnose your problem quickly and effectively. Over 300 companies have used our facilities regularly to ensure product consistency, so whether you need to independently verify a spring outside your own facilities, or want to test a products performance, fatigue testing is essential to fully understanding if your springs will function when needed.