What is Materials Testing?

Material testing is for the spring manufacturer or end-user to have confidence that the material they receive is as expected for that grade. The tests we perform are based on the requirements of national and international standards for spring material.

A wide range of techniques and tests are required in these standards, and we have the capabilities and expertise to perform them all. Examples of the tests stipulated in these standards are summarised below.

Explore Our Materials Testing Services

Torsion Testing

This test involves using specialist equipment to uniformly grip a specified length of wire at either end, keeping the wire as straight as possible. The wire will then be rotated at one end while counting the number of turns before failure, determining the wire’s ductility during twisting. This is important because it is typically stipulated in the wire standard and indicates its ductility under a torsional load. Both compression and extension springs apply a torsional load to the wire during operation.

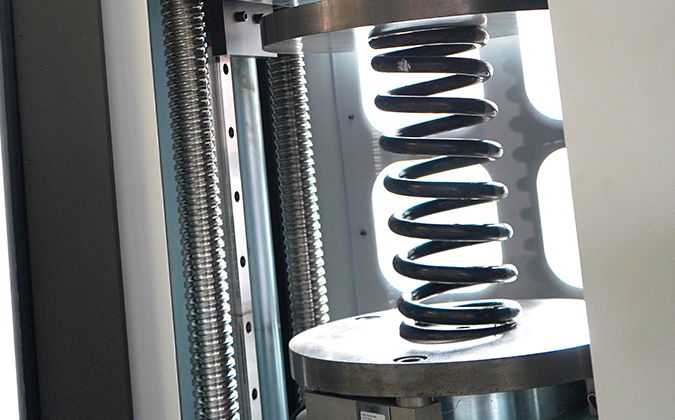

Tensile Testing

This test applies a tensile load to the material (usually wire) until it fractures. The results can then be used to calculate the material’s ultimate tensile strength (UTS or Rm). Both are typically specified in spring wire standards and are required for a wire to meet the specification. This test can also be used to determine Young’s modulus and yield strength if needed.

Wrapping Test

This test wraps a wire around a mandrel a specific number of times to form a tightly wound helix. The number of turns required and the diameter of the mandrel is stipulated in the wire standard. During this test, the wire must not fracture, and the surface of the wire must remain free from cracks. This determines the coilability and elasticity of the wire and can be used to test the adhesion of the zinc coating on galvanised wire.

Bend Test

This test involves bending a wire, which can move freely, over a mandrel of specified diameter, through a specified angle at ambient temperature. Like the wrapping test, this should result in an unbroken and unblemished wire and tests the ductility and toughness of the wire.

Coiling Test

Similar to the wrapping test, a wire sample is tightly coiled around a mandrel. This helix is extended so that the coils are separated once the extending force is removed. The pitch of the coils is examined to find abnormalities in the helix, highlighting any defects which could affect the coiling of springs.

Vicker’s Hardness Testing

This test uses a specified force to indent a polished sample with a pyramid-shaped diamond. The indent left on the surface of the sample is then measured and converted into a hardness. The result is typically used as a measure of the strength of the material when the size of the material is too large to be widely tested using a tensile teste

Optical Metallography

This involves sectioning a small section of wire and mounting it both in the longitudinal and transverse directions. This is then ground and polished to a 1-micron finish. This sample can then be examined under an optical microscope to determine the type and size of defects on the surface of the wire and coating thickness. This is an essential test for wires manufactured to dynamic grades as surface defects can cause fatigue failures and therefore have size limitations within dynamic material standards.

The microstructure of the wire is examined, checking it aligns with the expected microstructure for that specific grade. We check it does not contain any defects, such as decarburisation or induced martensite, which could affect the material’s performance. Decarburisation depth and amount of induced martensite and microstructure are all requirements for spring wire in a large number of international standards.