Great spring design software is integral to the smooth operation of any engineering or manufacturing business. Trusting that a key component is up to the task is imperative to safety within many sectors including the automotive, aeronautical and medical industries.

Providing valuable insights into material data and standards can help in cost efficiencies as well as cutting time in more traditional spring design test methods. Here are 3 things every piece of spring design software should have to help your company.

1 – Integrated Performance Data

Data is power and great spring design software should have it in abundance, learning from past experiences and adapting helps improve safety, promotes innovation and saves you money.

Since the Institute of Spring Technology’s (IST’s) original conception in the 1940’s fatigue and material test data has been amassed and used to form a basis of spring design standards. Utilising this 70 years worth of performance data and integrating it into Spring Calculator Professional software (SCP) has proved to be an exceptional feature and a huge asset for all spring manufacturers and designers.

Without this fundamental data there are no means of easily and effectively testing the integrity and longevity of a spring before it had even gone into production.

2 – Design Standards

This goes without saying, if you want to design a spring you need to be able to test against the latest standards and tolerances worldwide – BS, DIN, EN, IS, JIS, ASTM/SAE are a must. Not only this but the inclusion of wire specifications allows precision design and testing before a decision to purchase materials has even been made.

IST has integrated nearly 300 wire specifications into the SCP software – this wealth of knowledge keeps standards high and products working to life expectancy and beyond.

3 – Flexibility

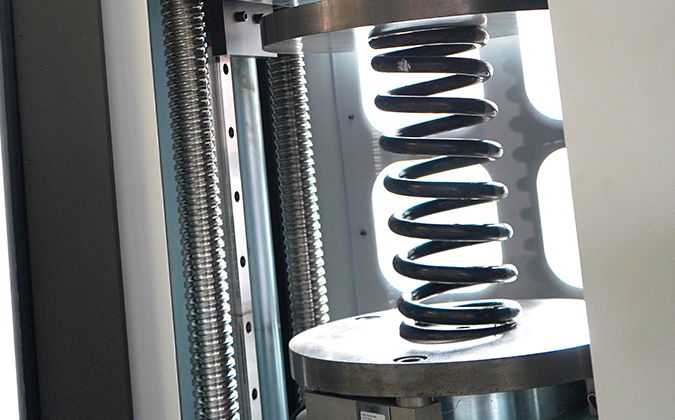

The flexibility of choice is a huge bonus when it comes to choosing software for spring design; SCP offer 8 spring types including compression, extension, torsion, conical compression, rectangular wire compression, non-standard round wire compression, disc and spiral spring – the most comprehensive choice on the market.

Goodman diagrams, Load / Length, and other graphical tools help evaluate the design. In addition test your spring with real-world constraints, such as limited space for the spring in the finished equipment.

These features allow designs to be quickly edited and the impact of changes in materials, standards and parameters to be easily evaluated.